-

+86-13404286222

-

hmjxboss@gmail.com

INQUIRE NOW

+86-13404286222

hmjxboss@gmail.com

INQUIRE NOW

Heat-resistant alloys are alloys that perform well at high temperatures, which means they have high creep resistance and strength at high temperatures. The heat resistance levels of these alloys are confirmed by two physical properties, which are the structure of the alloy and the strength of the interatomic bonds within it.

Heat-resistant alloys are classified by their base which could be nickel, iron, titanium, beryllium, and other metals.

This alloy is used in the field of gas turbine components and cryogenic storage tanks. Alloy 718 is commonly used in jet engines, pump bodies and parts, rocket motors and thrust reversers, and hot extrusion tooling. Other popular uses are high-strength bolting and down-hole shafting.

Alloy 718 is a high-strength, nickel-base, superalloy used for cryogenic temperatures up to long-term service at 1200 °F. This alloy is readily fabricated and may be welded in either the annealed or precipitation-hardened (aged) condition. 718 is annealed at 1700-1850 °F and air-cooled or faster. It is aged at 1325 °F for 8 hours, furnace cooled to hold at 1150 °F, for a total aging time of 18 hours, then air cooled. Alloy 718 will show a contraction of 0.0008 inch/inch after precipitation hardening.

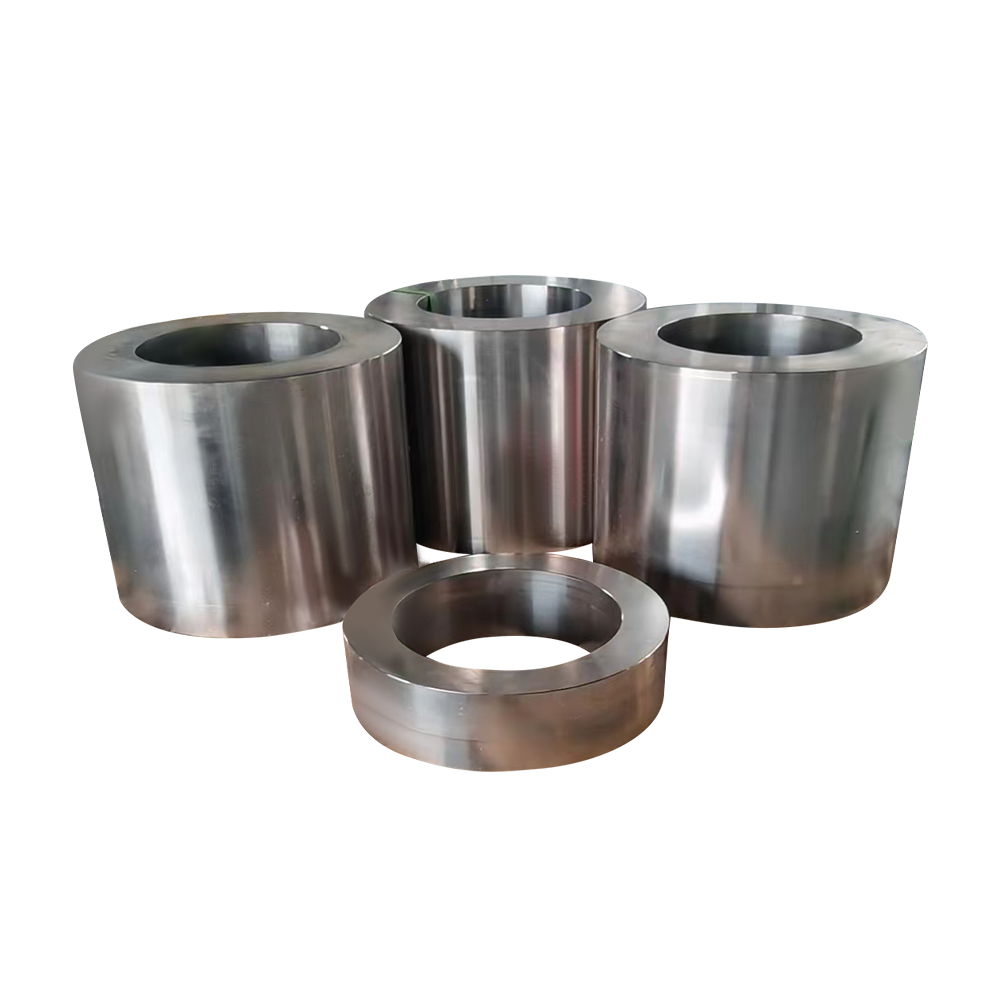

The typical properties listed can usually be provided in rounds, sheets, strips, plates, & custom forgings. We have the equipment to produce small quantities in special sizes to meet our customers’ specific needs. The table below shows Special Metals' Nominal Room-Temperature Mechanical Properties of Alloy 718 Bars, Forgings, & Rings, and Sheets, Strips, & Plate. For common forms and exceptions, check out the datasheet linked underneath the table.

| Form | Spec. | UTS ksi (MPa) | YS ksi (MPa) | Elong. in 2 in., % | Reduced Area, % | Hardness |

|---|---|---|---|---|---|---|

| Bar, Forged, & Ring | AMS 5662 & 5663 | 180-185 (1241-1276) | 150 (1034) | 6-12 | 8-15 | 331 BHN |

| Sheet, Strip, & Plate | AMS 5596 | 180 (1241) | 150 (1034) | 12 | HRC 36 |

UTS = Ultimate Tensile Strength, YS = Yield Strength